Here you can find some of the most frequently asked questions regarding Brick Brace support tools, technical facts and how to use our products

How Can I reduce risk from overloading eccentric Acrow props?

Structural Instability, vibration, unknown or further dynamic loads and inadequate or no remedial works creates a higher risk of overloading. Learn how to strengthen a structure to prevent sudden shockwaves reaching the bendable tongues to significantly reduce the risk of collapse.

Make it part of the required remedial works preparation to prevent collapse from overloading, as the load of a braced bonded brickwork structure weighs considerably less than the load of an un-stable brickwork structure.

To perform structural alterations to a superior standard, each project is to be planned upon its own merit to ensure the correct variety/combination of equipment is chosen. The Brick Brace provides the missing factor of safety. Stabilising the structure to reduce the load, supports the un-held masonry in-between props, (to prevent falling debris) and provides further scaffolding/fitting/working access without overloading.

Adapt safely to the Brick Brace by fitting over a proposed brickwork opening before propping to eliminate partial collapse in-between props, to prevent sudden shockwaves of increased loads onto the bendable tongues and significantly reduce the risk of collapse from equipment failure.

Where can the Brick Brace be used?

The Brick Brace is designed to support 4” masonry and used to create openings within existing masonry, providing the correct fitting access/work space to fit lintels & steels safely and correctly. Replace lintels, fit new cavity fire protection, cavity trays & D.P.C’s with ease. Re-instate a load-point to reduce the weight of the load when propping. Use the Brick Brace as an under-pinning aid to strengthen & stabilise lime mortar masonry and to aid all remedial works, brickwork renovations & repairs.

What supports the inside skin?

When fitting steels for cavity or solid walls, it’s not possible to choose the most suitable equipment without knowing the following information:

1: The materials, build/design and the structural stability of the wall

2: The direction and depth of existing joists

3: The fabrication and dimensions of steel/steels

4: The finished height/position of the steel/s compared to existing joists

The vast majority of cavity lintels & steels are fitted from the external side. Use the Brick Brace externally upon cavity walls when the internal can be propped separately from inside.

Why use a scaffold tube and what size?

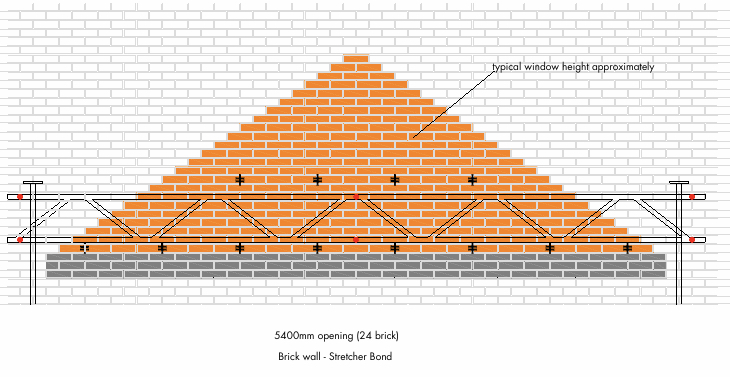

A normal scaffold tube size 48.3mm (either steel or preferably aluminium due to the lower weight) connects each individual safety tool to the next with all the single tools becoming one piece, sharing the load equally over the length of the opening and building a temporary pre-stressing lintel within the brickwork above, to ensure no movement when the masonry is removed from below.

What does the Brick Brace do?

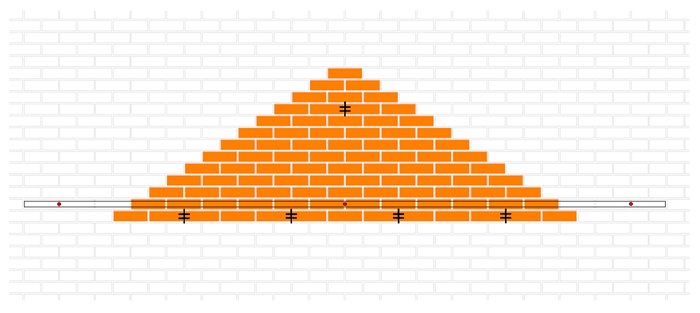

The fully tested Brick Brace supports by pre-stressing the masonry to prevent collapse, half set allowing openings within existing 4″ masonry up to 3,150mm (14 Brick Lengths)

5,400mm (24 Brick Lengths) with the full set, without the use of any impeding Acrow props upon the fitting/work side at any height, high or low and enhances all the traditional propping methods to reduce the risk of major collapse through overloading and prevents minor collapse in between props.

The stability and lateral strength of masonry is unpredictable and varies; depending on the length of an opening, the mortar mix, the age and the quality of the masonry.

All existing propping methods rely on the unknown lateral strength to work safely: the fully tested Brick Brace safety tool increases the unknown variable strength of masonry by creating a force of 40Nm which through testing is proven to be strong and stable enough to prevent collapse during alterations.

The Brick Brace, guidance, correct procedures, weight charts and proven strategies address all the main causes of minor and major collapse during masonry alterations.

Brick Brace instructions and downloads for further reading: Instructions and Downloads Page

How far from the corner of a building can the Brick Brace be used?

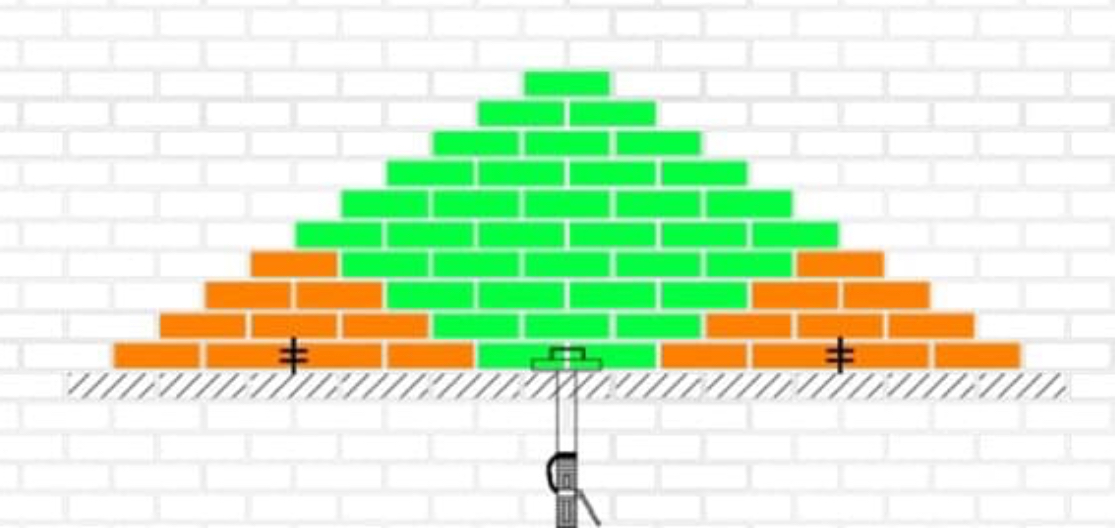

When used without props, the Brick Brace safety tool/system is designed to support the triangle of masonry above an opening and requires a minimum of one brick as a reveal or from a corner as theoretically the load is transferred to either side of the opening.

Why use the Brick Brace when Strongboy’s are so easy to use?

The main cause of collapse is through overloading equipment, which is systematic problems of equipment; the hidden risks of eccentrically loading an Acrow prop, the clarity of use, a variable working load, inadequate training, no safety factors and insufficient testing. It’s urban myth that the Strongboy is suitable for every task, with the misleading instructions changed by enforcement of the H.S.E in November 2015 and now read;

“Before using a Strongboy you should identify that it is a suitable method to carry out the intended works”.

Self-employed builders, employers and employees working within construction can only discharge their obligations under British legislation (C.D.M 2015) to the extent that the relevant information provided by manufacturers, retailers, the structural engineer and the H.S.E allow. Where the information and guidance is either absent, assumed, doctored, or insufficient, as would generally appear to be the case with regards to both the eccentrically loaded Acrow prop and the tongued prop attachment, it is not possible for these obligations to be satisfactorily met. Workers are not in possession of the correct information to be judged truly competent to make informed decisions and/or to identify the risks to an acceptable standard, especially when the hazards are unusual and hidden from the workers view; as they are concealed by no warnings, a lack of guidance and also hidden within the products testing un-certainties, flaws and faults.

Both products lack basic information about compatibility with each other and a safe configuration of use. The out-dated and double entendre maximum safe working loads are quoted for both components individually and not for use together of which has created a false sense of security to the end user when not tested together.

Inadequate Design/Safety Factor calculations and no Working Load Limit (WLL) is used, when the existing out-of-date, maximum safe working load is clearly taken at a measurement of 215mm of eccentricity of the old/redundant written instructions.

The increased measurement of eccentricity within the new written instructions is now 365mm, (150mm further eccentricity). This working load is clearly variable due to a greater distance of eccentric loading, (further from the Acrow props central axis) and is clearly inadequate which requires both products to be tested together; to clarify an acceptable working load limit of which should include a correct factor of safety calculation, normally X10 if a work-force is working underneath. This would prevent further accidents and will also protect workers, clients and the general public as it is not possible to manage health and safety when a product is supplied with hidden risks and incorrect guidance and is permitted to be used to prevent internal wall damage upon occupied living accommodation structures and when open plan living design has increased the size of openings within a typical rear extension of a property. A structural engineer providing and deceiving a client with false information/guidance that is purchased in good faith, is not only dangerous but also fraudulent.

We created the Brick Brace to counter act all of the hidden systematic problems of eccentrically propping and to make masonry alterations more controllable, safer and easier during the task and to ensure future generations are taught correctly. Research click here

We know safer and superior methods and also provide guidance to help, teach and influence the majority to change their bad habits.We don’t endorse the misuse of any temporary support equipment however anyone that continues to overload tongued prop attachments through over extending from the wall to gain sufficient fitting access, we highly recommend bracing the masonry beforehand to reduce the risk of collapse, especially within lime mortar masonry.

How do I adapt to the Brick Brace?

To experience the difference, read the instructions provided and use the Brick Brace for the first time when also propping to experience the difference. We offer a full money back guarantee to anyone that follows the instructions and doesn’t benefit from its use. The more methods known, the safer and easier the different tasks of altering masonry become.

How can the Brick Brace support brickwork that has dropped or sagged?

Prop the brickwork with the Prop-Wise or similar until the brickwork is back inline and then fit the Brick Brace to strengthen the brickwork and to keep in position. The masonry below can now be removed and upon smaller openings the impeding props which were used to level the brickwork can be removed for a superior working access.

Can the Brick Brace be used internally?

That will depend on the existing ceiling heights and the size and fitting height of permanent support. Every task of masonry alterations is different and should be planned upon its own merit when using a variety of temporary masonry support equipment most suitable and to not only dangerously misuse Strongboy’s for every task when there are now further methods available.

Why is the Brick Brace not in the Shops?

The vast majority of retailers do not fully understand that the tasks of altering masonry are different and do not know how to sell temporary masonry support equipment safely or correctly.

We have raised the standards and until retailers prove to us they have also raised their standards and learn how to sell their existing temporary support equipment safely we will continue to sell direct to the end user to ensure the correct level of guidance is provided.

What Law?

Construction, Design and Management, in force since the 6th April 2015 and is British legislation. (Temporary Works in Brief)

Regulation 19 – (Stability of structures)

All practicable steps must be taken to prevent danger and ensure that any new or existing structure does not collapse or become unstable due to the carrying out of construction work.

Temporary support must be designed, installed and maintained to withstand foreseeable loads and only used for the purposes for which it was designed for. A structure must not be loaded as to render it unsafe to any person.

Work within health and safety guidelines; respect your legal responsibilities and the welfare of others around you.

Which propping method should I use with the Brick Brace when fitting steels over 3 metres in length?

That will depend upon where the steel is to be fitted:

When fitting a steel under joist height & creating a seen bulk head, tongued attachments can be used internally, with the Brick Brace used externally. Where steels are fitted level with existing joists, the props and needles method fitted over joists is more suitable with the Brick Brace also used externally.

Where are The Brick Brace fitted?

Within the full course directly above a proposed opening and fitted three bricks apart in a cement mortar mix, a maximum of two and a half bricks apart in a weak or lime mortar mix and within every perpendicular joint upon Block work, full instructions of correct use are supplied with every order and also available to read/print from our instruction/download page.

Will the force of the Brick Brace push out the Brickwork?

Not at all, the fully tested Brick Brace safety tool uses only a fraction of the force required than propping. A torque of 40Nm produces a force more than enough to brace and support the masonry even allowing for some fall off in force as the tools bed in, (Factor Of Safety X 3). The torque is also readily achievable on site with a ratchet spanner and provides a force well below that to crush the face of the brick, with no distress whatsoever and with no visible movement or cracking.

How can the Brick Brace reduce the number of Acrow props?

Single Brick Brace safety tools are used to re-instate a load-point which safely reduces the weight of the load that requires support.

Within a typical two storey residential property, correctly used props are under-loaded when positioned at 900mm centres when a load-point is intact, therefore props can be positioned at 1,350mm centres when single safety tools are fitted in between props, this safely reduces the number of props by 50% from the work area.

What tools are required to fit the Brick Brace?

To fit a single safety tool you require the use of a hammer drill with a 10mm masonry drill bit to remove the perpendicular joint and a 19mm socket spanner to expand the Brick Brace. The Brick Brace system requires a Hammer Drill, 8mm and 10mm masonry drill bits, 15, 19, 21mm sockets and a ratchet. The 40Nm torque required to expand the Brick Brace is similar to tightening a scaffold fitting. To remove the masonry below use a disc cutter and a light set hammer drill with the correct chisel fittings, a masonry or traditional hand saw is sufficient for lime mortar mixes, full instructions and a correct procedure are provided and available to read or print via our instructions/download page.

Can the Brick Brace be used on load bearing walls?

Of course, however Acrow props and spreader plates should always be used to prop load bearing joists and beams separately, which safely supports the different possible live and static loads they may be carrying.

As with a Strongboy the Brick Brace safety tool is not a substitute for a concentrically loaded Acrow prop. Position props a maximum 600mm from the wall when supporting joists giving enough room to work. The condition of Joists and beams must always be checked before propping, please read our 2020 masonry wall propping guide for further information on the correct use of an Acrow prop.

Does the Brick Brace have certification?

There is no certification, British standard or kite mark available for any temporary masonry support equipment, as it’s not a permanent fixture. The Brick Brace Safety tool was fully tested in multiples and complies with the provision and use of work equipment regulations.

Does the Brick Brace have a guarantee?

Anyone that uses the Brick Brace safety tool that does not benefit from its use we promise a full money back guarantee. We ensure every user has the information to tackle every task safely as we supply full instructions & a correct procedure with every order and we provide a further help-line so no assumptions of use need to be made.

We have studied temporary masonry support for many years and our fully patented method of strengthening masonry is the further preparation required for safer and superior results, GUARANTEED.

If you have any other questions, just ask our temporary support expert Anthony on his mobile: 07545 462463

C.R.O.S.S – Confidential Reporting On Structural Safety

When carrying out temporary needling and propping one of the most important aspects is to ensure that the props are concentrically loaded and plumb. The use of a steel bracket on top of the prop giving a minimum eccentricity of 200 mm would not seem to be such a good idea?

Interestingly such a product does exist and has proved very popular with builders who see it an advantage to prop only one side of a wall.

The prop is sold and hired from builders’ merchants with minimal safety instructions and is potentially unsafe due to bending moments being introduced by this product into Acrow props designed only for axial compression. Any device that modifies the behaviour of props by introducing bending moments is potentially hazardous.

Another reporter has come across these in use and in his view they must only be used in the case of limited openings where the masonry can arch over leaving only a small triangle of masonry below the arching that can potentially break away.

All in all these are for light use only and never for heavy shoring. The reporter thinks that the manufacturers and possibly the hire companies would be negligent if they did not provide some guidance on the use of such props.

Another reporter has frequently seen builders using props with cantilevering head-plates which cause the supporting props to bend. Some years ago he photographed a set of such props which had very noticeable curvatures. The wall above had dropped in consequence causing damage to the building and resulting in a substantial claim against the builder. The reporter generally advises builders not to use such head-plates.

The Brick Brace Safety Tool, our guidance, weight charts and proven strategies address all the main causes of minor and major collapse during masonry alterations

Brick Brace review spotlight:

By Lateral solutions group Ltd

“Having been a builder now for over 30 years, I could be justifiably accused of being stuck in my ways in certain aspects of the building trade, one of those areas are removing sections of load bearing walls and creating new window and door openings, tools required, Props, Needles and Strong boys . . . . . Not anymore! After reading an article regarding safe working loads when using Acrow props, in a nut shell the load calculations are as follows:

…….

An Acrow prop, max S.W.L is 3,400Kg

Two Acrow props and a needle method this is then reduced to max S.W.L 1,700kg

An Acrow fitted with a prop attachment (Strongboy) this is then reduced to max S.W.L 340Kg

So with a little research on the best kept secret in the building trade . . .

Brick Brace steps into the ring!

I’ve used this product now for nearly 1 year, first of all, it’s like carrying around 12 Acrows,5 Needles and two Strongboys in a small tool box, Great start!

Secondly, does it work and How?

The answer to the first question is an easy yes it does!

The answer to the second question, without sounding like a salesman for this product is as follows:

A single brace that fits in your hand can support an opening of up to 1575mm opening supporting the full triangle of Cement, mortar and masonry above.

With the full kit, as mentioned carried in a small toolbox capable of supporting an opening of up to 4500mm with the use of only 1 prop to the middle! No Acrow hindering access for the installation of steels, no repairing brickwork above where to needles were! Window opening above ground floor. . A breeze!

Finally in my opinion . . . IT’S A KNOCK OUT!! Brick Brace wins, hands down!

I have now vowed as a builder to stop living in the dark ages and start moving forward with new equipment and new methods of construction.”

…….