Prices Include VAT & UK Delivery

Quarter Set £110.00 – Clear access on Openings up to 1800mm in a lime mortar mix and up to 2250mm within a cement mortar mix

Half set £180.00 – Openings up to 3,150 mm (14 brick lengths) at any height high or low, with full access to the task

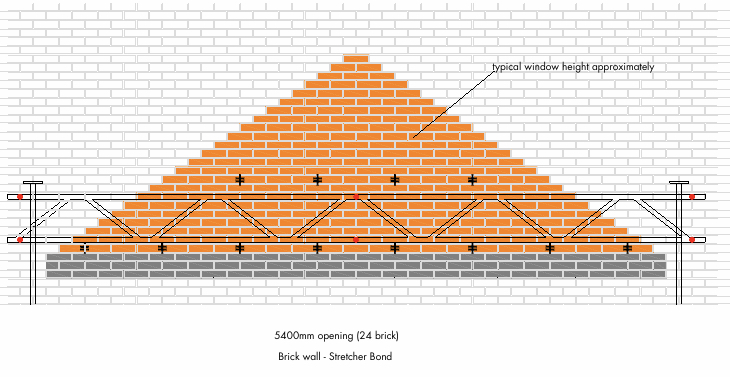

Full Set £320.00 – The Brick Brace safety system allows openings up to 4,500mm (20 brick lengths) when using only one Acrow prop fitted central and scaffold clipped to the horizontal scaffold tube

Openings up to 5,400mm with full fitting access when using a 6 metre aluminium scaffold beam over the opening.

Also use above larger openings when needling, to hold the brickwork in-between props and to support the masonry as one whole piece to reduce the risk of minor & major collapse.

Instructions & Downloads, Click Here

–

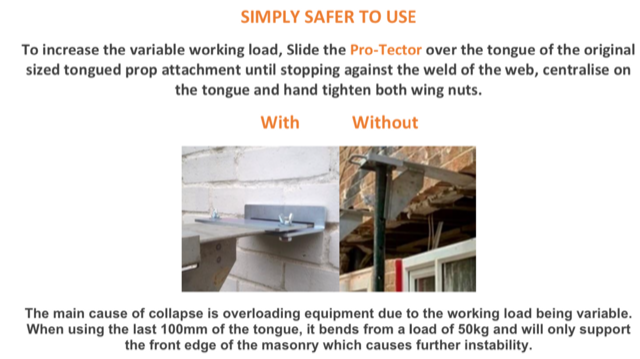

Builder error is not a cause of failure, it’s the effect and symptoms of deeper trouble of existing equipment, the clarity of use and inadequate safety factors and testing. Human error is not random, it is systematically connected to features of people’s tools, tasks and operating environments.

NEW

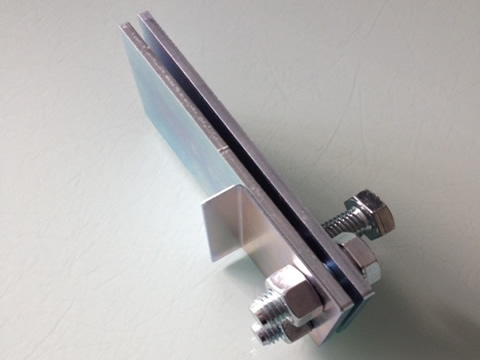

The Eccentric Prop, Pro-Tector £36.00 Inc VAT & UK Delivery

Pro-Tector Product Information & Guidance; CLICK HERE

–

PROP-WISE

Reduced eccentricity = A superior and safer working load.