The Brick Brace Safety System – Single Tool – Price includes free delivery within the United Kingdom – We also ship to the United States and Canada (US and Canadian shipping costs are weight based and shipping prices are calculated at checkout) – For other international/overseas orders, please contact us directly for a shipping quotation.

Brick Brace – Single

£24.00

Description

THE AWARD WINNING BRICK BRACE SAFETY TOOL

GUARANTEED SAFER, SUPERIOR & EASIER MASONRY ALTERATIONS OR YOUR MONEY BACK!

Only £24.00 Inc VAT and Delivery Anywhere Within the UK

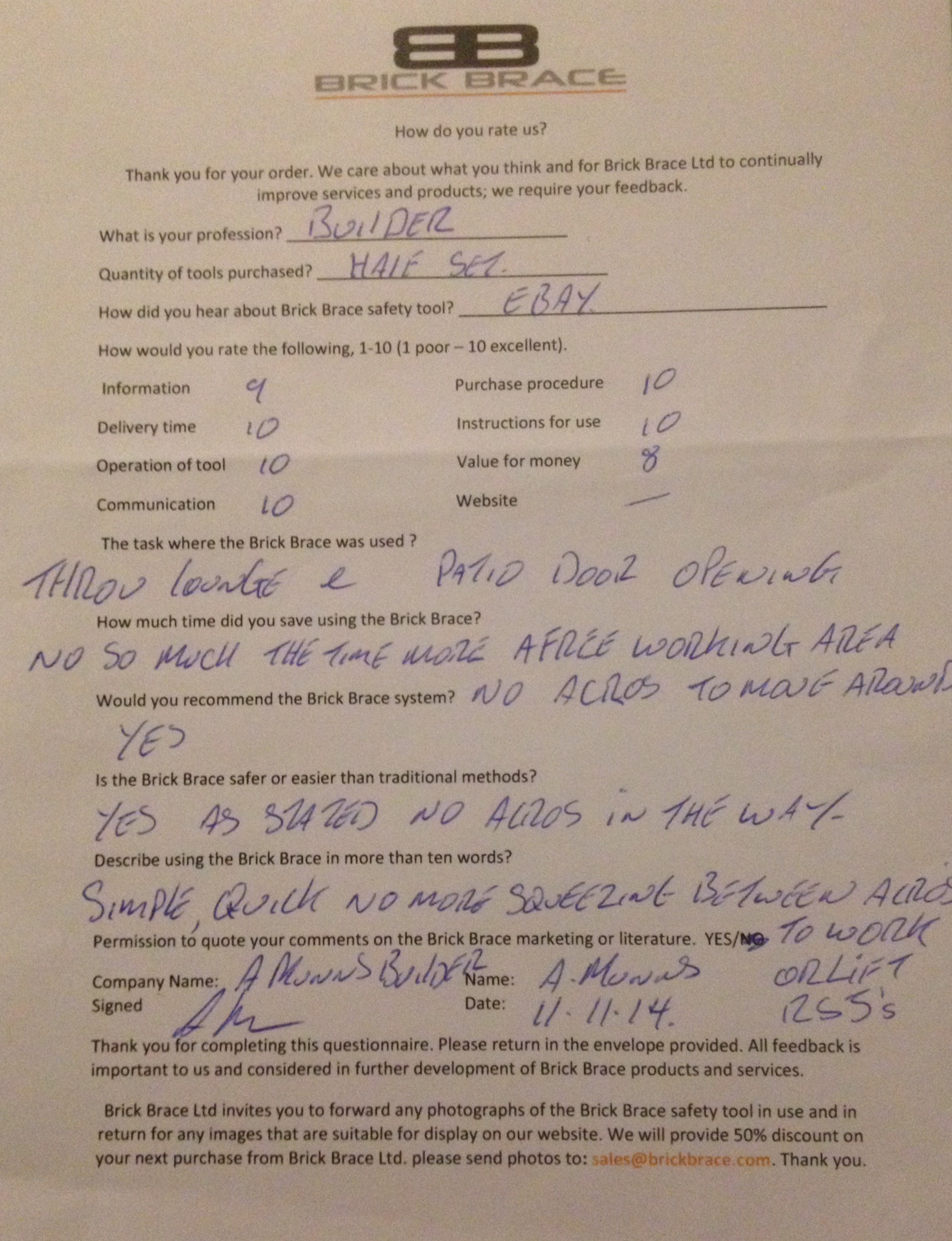

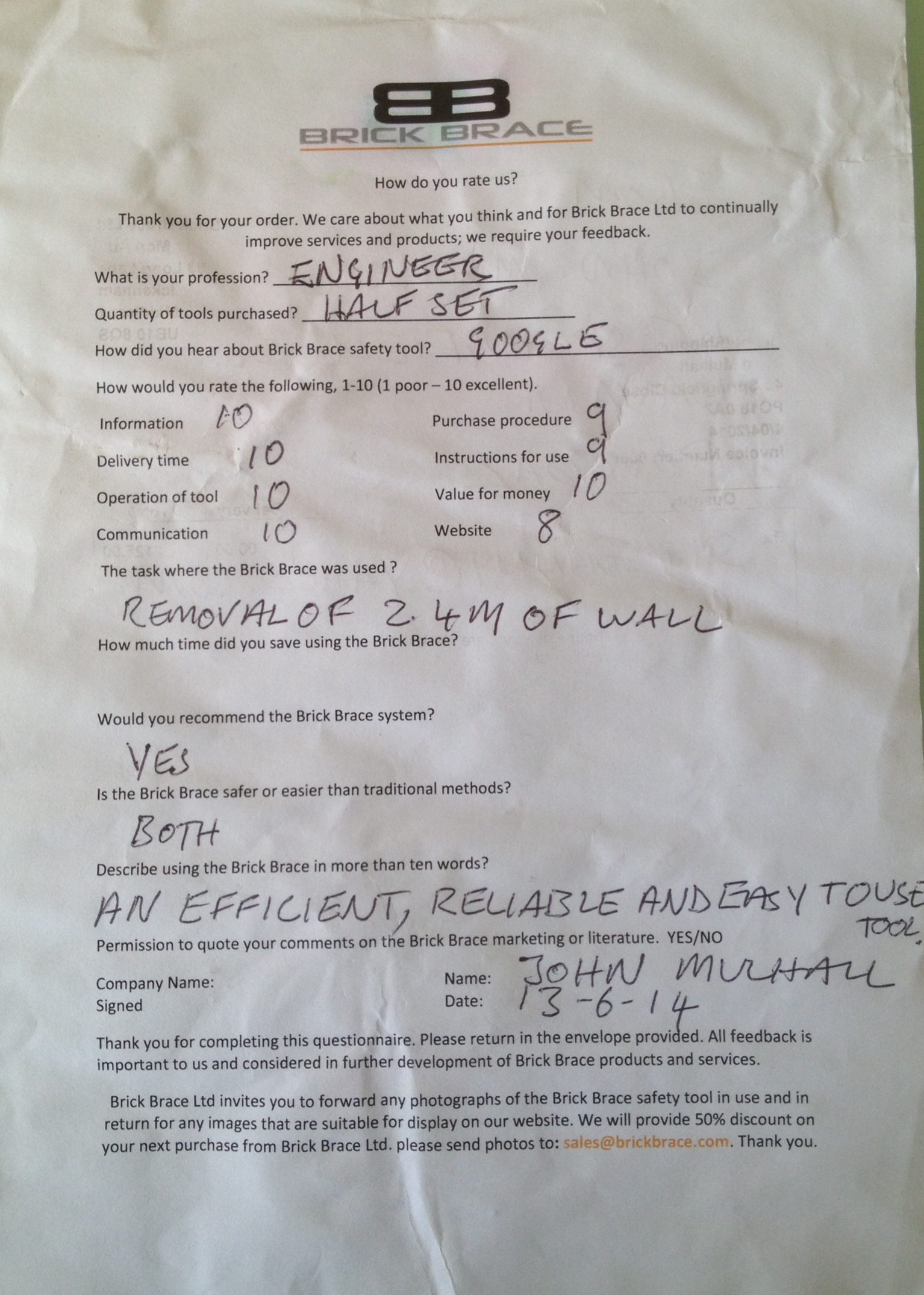

BRICK BRACE FEEDBACK

Mr S. Dunaway

(Builder, Surrey)

Top quality product.

“After taking the time to read and understand what the Brick Brace has to offer, I can now appreciate the impact this system can have on improving the safety of structural alterations.

After all structural alterations are the only general construction based procedures where NO training or advice is offered to any tradesman”.

“For me, Brick Brace is not just a product; it has provided an understanding of the task, with clear guidance on the limitations of all the equipment.

I also received very helpful advice and instructions from the guys at Brick Brace regarding my own project.

I challenge you all to find another company so invested in your own safety when it comes to structural alterations”.

For Every Builders Tool Box

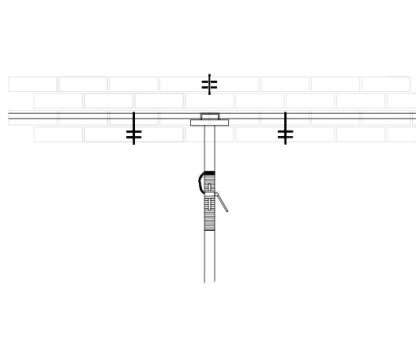

Using The Brick Brace; Step One

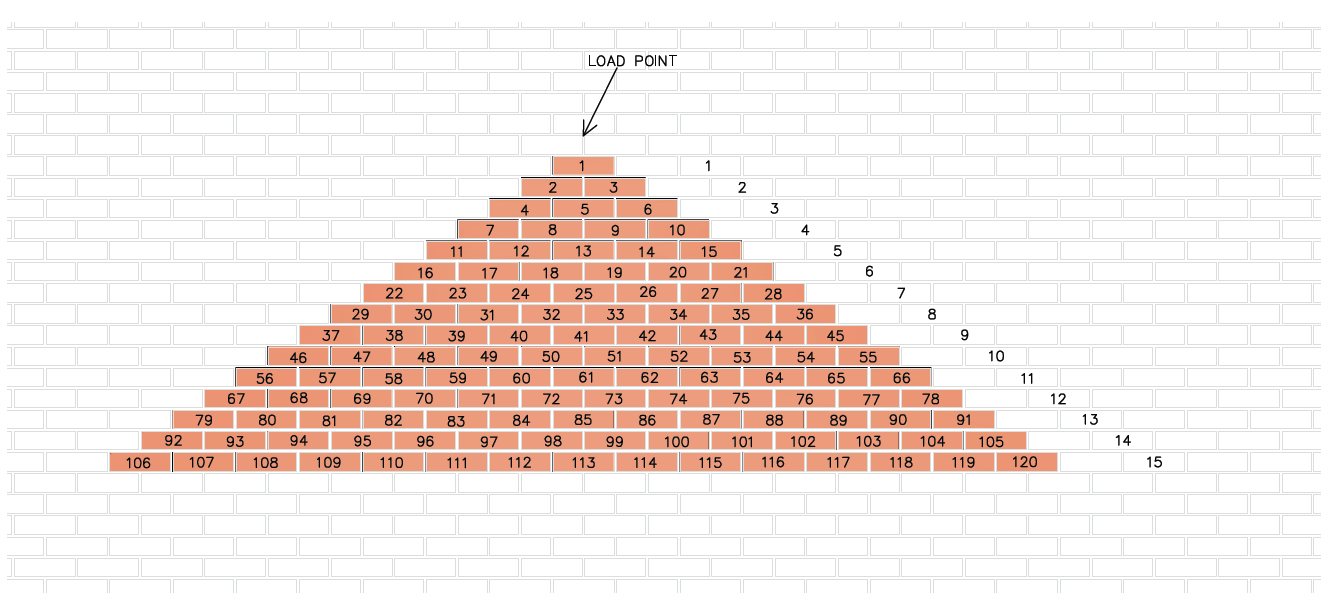

Load-Point?

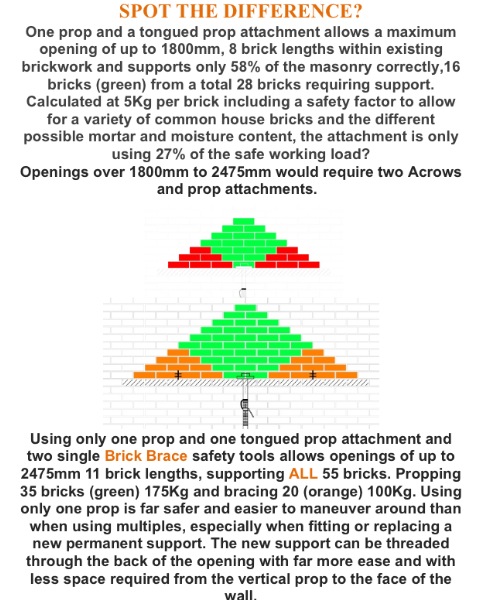

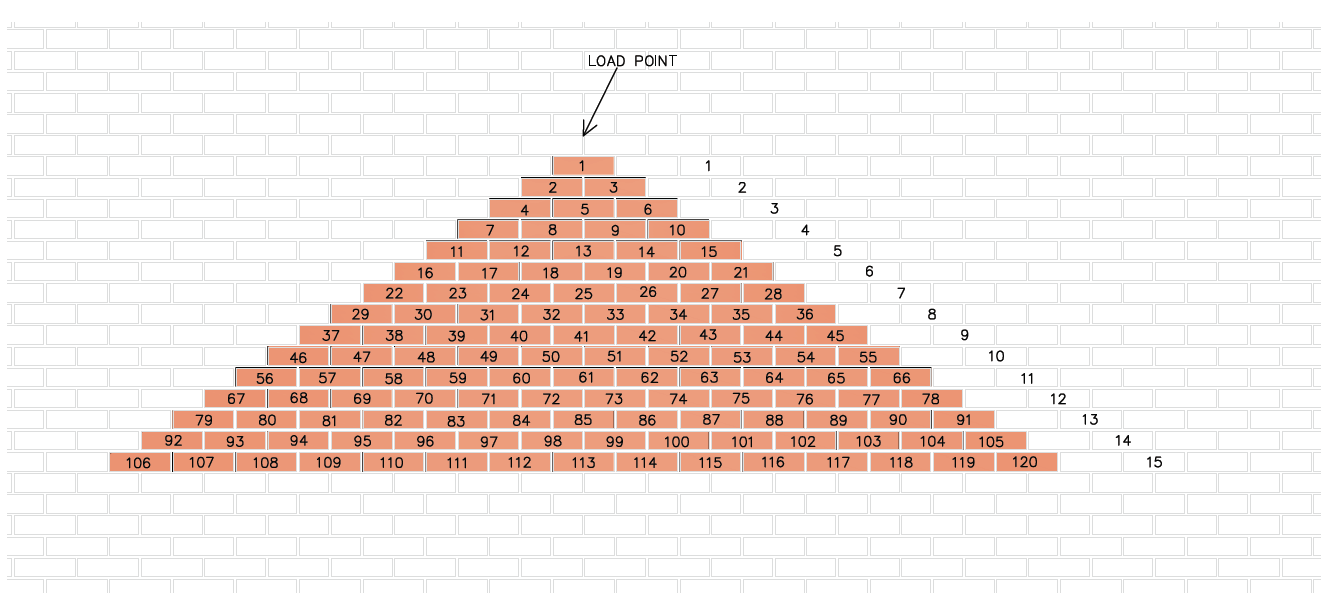

A 35 degree angle in a stretcher bond and a 25 degree angle in a Flemish bond from both ends of the opening, carrying up to the central perpendicular joint where both angles meet is the load-point.

When an opening is made within an existing wall and a load point is intact. the triangle of brickwork above the opening is the only masonry that requires support due to the brickwork above naturally arching.

However, upon larger openings and the 3 points do not remain, this law changes. And the weight of all of the storey height rests back over the length of the opening, due to the brickwork not having the correct arching effect,

This masonry can weigh up to 10 times more than only the small triangle and is why tongued prop attachments are so easily overloaded.

Re-instate A load point

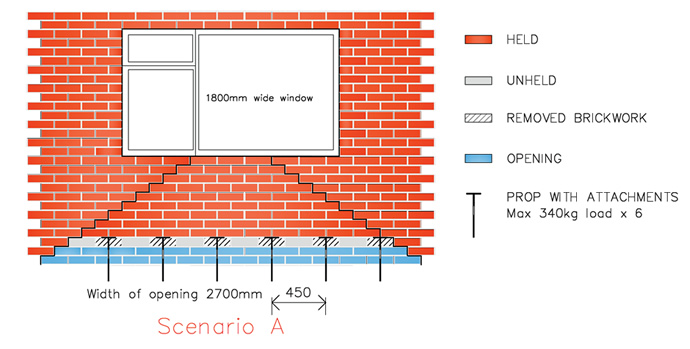

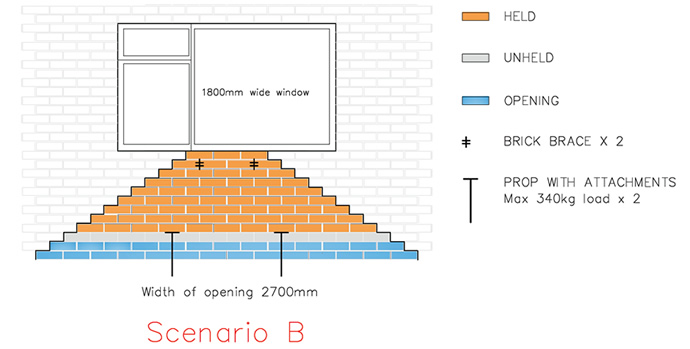

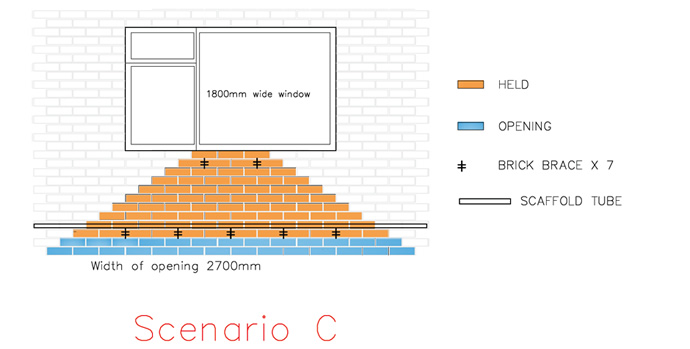

Fit the Brick Brace Safety tool through the top of a broken triangle and it becomes complete, reducing the load to a minimum and safely reducing the number of props required, cost effective without compromising safety.

The Brick Brace reduces the weight of the load to eliminate the main cause of collapse.

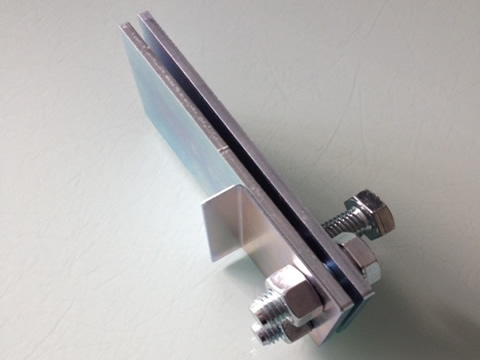

Single Brick Brace Safety Tools

To Fit the Brick Brace; use a hammer drill with a 10mm masonry bit to remove the mortar from the required perpendicular joint. Whether left or right-handed insert the Brick Brace safety tool into the drilled out joint with the centre set screw being on your favoured side and engage fully to the angled plate. Ensure the rear nuts allow both plates to run parallel with each other when the tool is expanding within the joint. To increase tool life, do not hammer the tools when joints are tight, use either an 11mm masonry drill bit, mechanical mortar raker or a file to increase joint size. Use a 19mm spanner/torque wrench to tighten the central set screw approximately 40Nm. The masonry is now reinforced and ready for safer alterations, clearer access and superior results.

A single tool can be used to create openings of up to six brick lengths upon 4” brickwork within a cement mortar mix, supporting all 15 bricks within the triangle of masonry above at any height with nothing to obstruct the fitting area and a five-brick length opening is achievable within a lime mortar mix. Ensure all three points of the triangle of brickwork above the opening are intact and the brickwork is free of voids.

When an opening is required within both sides of a cavity or 9” wall, it is recommended to brace externally and prop internally when suitable, leaving the external face side clear for scaffolding and working access, at any height.

Brick Brace Safety Tools are fitted within the course directly above a proposed opening at a maximum of three bricks apart in a cement mortar mix and a maximum of two and a half bricks apart within a weak or lime mortar mix.

Single safety tools are also used to stabilise the unpredictable lateral strength of a structure, to re-instate a load-point which safely reduces the weight of the load and used as an aid to support the un-held brickwork in between props to reduce the risk of minor & major collapse when propping.

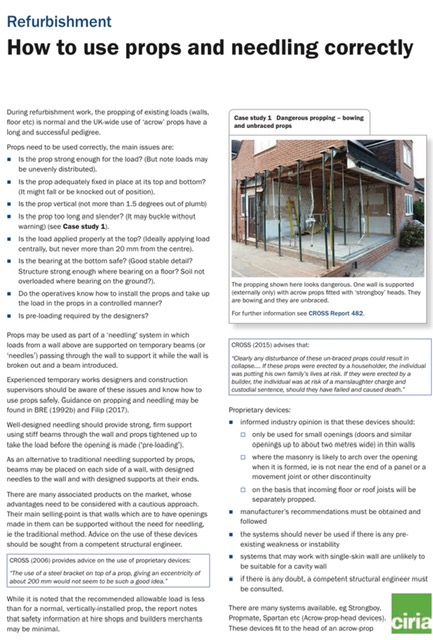

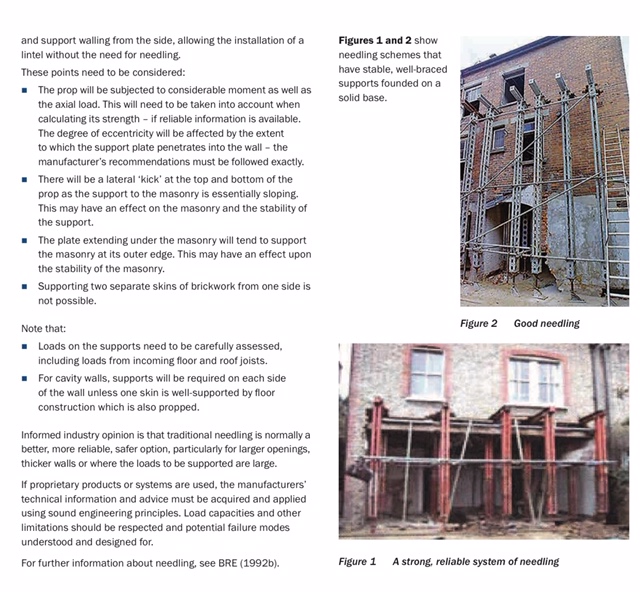

Prop & Brace; We do not endorse the misuse of any temporary masonry support equipment however as it’s become strangely acceptable to overload tongued prop attachments through over extending from the wall to gain sufficient access, we highly recommend bracing all eccentrically propped brickwork to prevent the same needless recurring accidents caused through overloading due to the unpredictable lateral strength of the structure.

APPLICATIONS

Fit a permanent support within existing masonry at any height with the correct fitting/work access. Replace lintels, fit new fire guards, cavity trays & D.P.C’s with ease. Re-instate a load-point to reduce the weight of the load and an under-pinning aid. Strengthen/stabilise lime mortar masonry to eliminate the risk of collapse and aids most remedial works, brickwork renovations & repairs.

We Are Here To Help You Adapt!

For unbiased advice regarding any masonry alterations task contact us;

Tel; 01895 546405

Or

Call Anthony On; 07545 462463

E-mail; sales@brickbrace.com

To help us help you, please read our 2023 masonry wall propping guide to ensure you give us sufficient information of your task.

Or

Book A Brick Brace Demonstration On your own project, from as little as £720.00, Includes ½ day training, the Brick Brace Full Set and VAT.

–

We created the Brick Brace to provide further options, to counter act all of the hidden problems of eccentrically propping, to make alterations easier to plan, to be more controllable, safer, easier and to ensure future generations are taught correctly.

Research; Identifying Hidden Risks; Click HERE

–

BRICK BRACE SYSTEM BENEFITS

Simple to adapt to

Re-instates a load point to safely reduce the weight of the load

Improves Masonry Alterations knowledge

Providing further temporary support options

Keyhole surgery for face brickwork

Full access to the task

Ensures future generations are taught safely & correctly

Use at any height, high or low

Stabilises lime & weak mortar masonry

Fully tested in multiples

Supports all of the masonry, even in lime mortars

Guaranteed superior finish to a task

Versatile & Lightweight

Raises the standards set within temporary support works

Also use when propping for total control of a task

Protection against minor collapse in-between props

Allows a prop to be manoeuvred safely during a task

Reducing the number of props required

Pays for itself within two applications

Reduced Repair time

Easy To Store/ Fits in a tool bag

Reduced carbon footprint

Designed & Manufactured in Great Britain.

Superior results and time saved

GUARANTEED

–

The award winning Brick Brace, instructions and guidance address all the main causes of minor and major collapse when altering a brickwork structure.

Additional information

| Weight | 1.0 kg |

|---|

J Williams –

Excellent product, simple and easy to use, saves time and hassle. Came with detailed instructions and excellent customer service if needed. Thanks.