The Brick Brace Safety System – Quarter Set – Price includes free delivery within the United Kingdom – We also ship to the United States and Canada (US and Canadian shipping costs are weight based and shipping prices are calculated at checkout) – For other international/overseas orders, please contact us directly for a shipping quotation.

Brick Brace – 1/4 Set

£110.00

Description

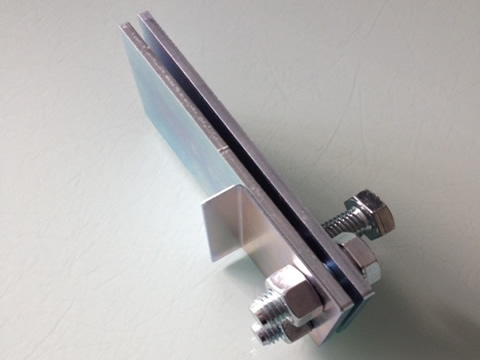

The Brick Brace Safety System

Quarter Set

3 Brick Brace safety tools, 3 safety hooks, 2 couplers, anchor bolts, full instructions, guidance & free delivery within the UK.

(Scaffold tube not included)

–

GUARANTEED SAFER, SUPERIOR & EASIER MASONRY ALTERATIONS OR YOUR MONEY BACK!

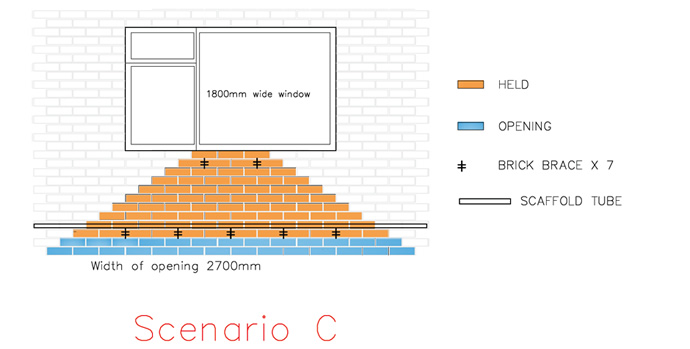

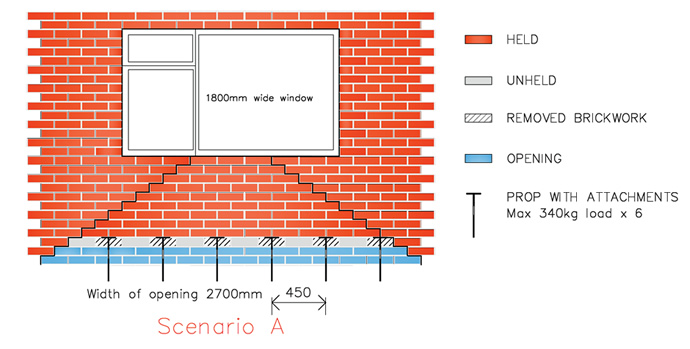

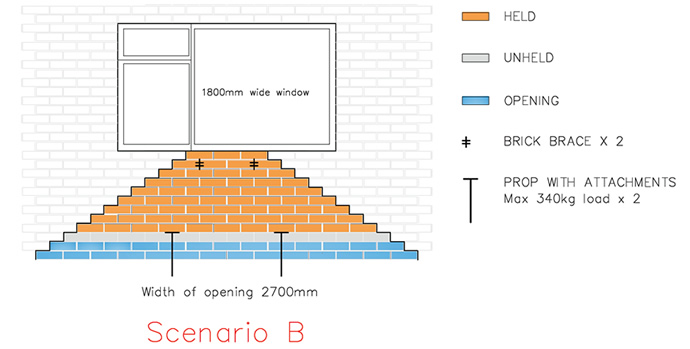

QUARTER SET PROCEDURE

Openings up to 2,250mm (10 Brick Lengths)

1. Drill & fit couplers at both ends, 120mm past the opening & measuring 120mm above the opening.

2. Fit scaffold tube and tighten couplers.

3. Remove the required joints; maximum of three bricks apart in a cement mortar mix and a maximum of two and a half bricks apart within a weak or lime mortar mix.

4. Fit hooks over the tube at the drilled-out perp positions, fit safety tools into prepared perps, remove both nuts, secure hooks onto tools, re-fit nuts and tighten the tools.

Additional Tools; Masonry Drill, 8 & 10mm masonry drill bits,15,19,21mm Sockets and ratchet/socket spanner.

Anyone that uses the Brick Brace safety tool that does not benefit from its use we promise a full money back guarantee. We ensure every user has the information to tackle every task safely as we supply full instructions & a correct procedure with every order and also provide a further help-line so no assumptions of use need to be made.

We have studied temporary masonry support for many years and our fully patented method of strengthening masonry is the further preparation required for safer and superior results, GUARANTEED.

If you have any other questions, just ask our temporary support expert Anthony on his mobile; 07545 462463 .

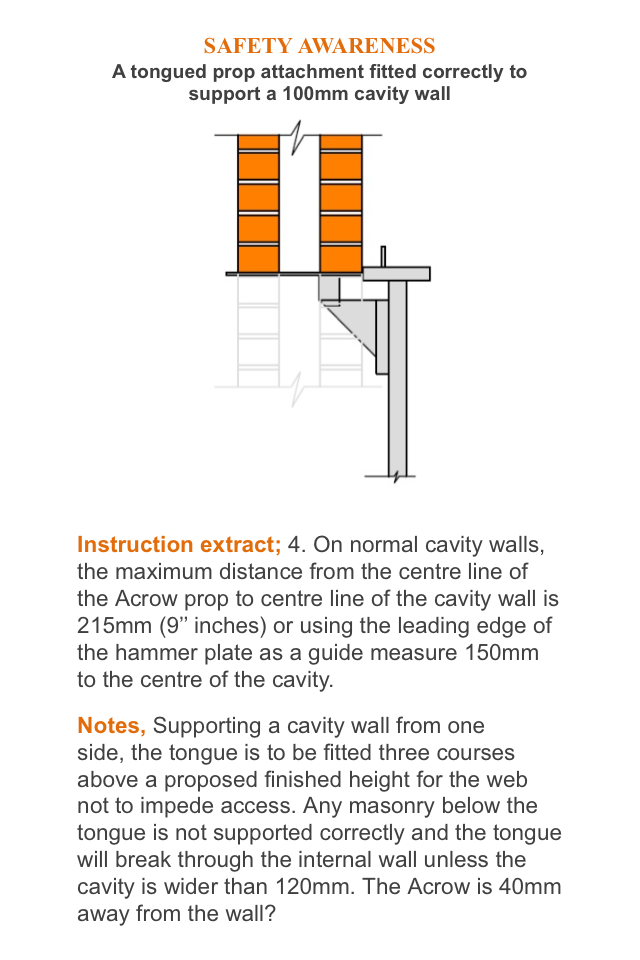

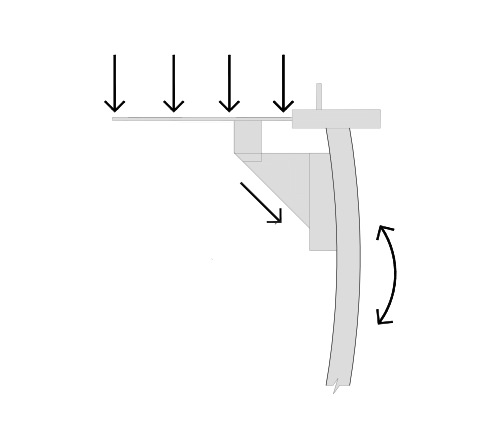

We created the Brick Brace to provide further options, to counter act all of the hidden problems of eccentrically propping, to make alterations more controllable, safer and easier during the task and to ensure future generations are taught correctly.

Research; Identifying Hidden Risks; Click HERE

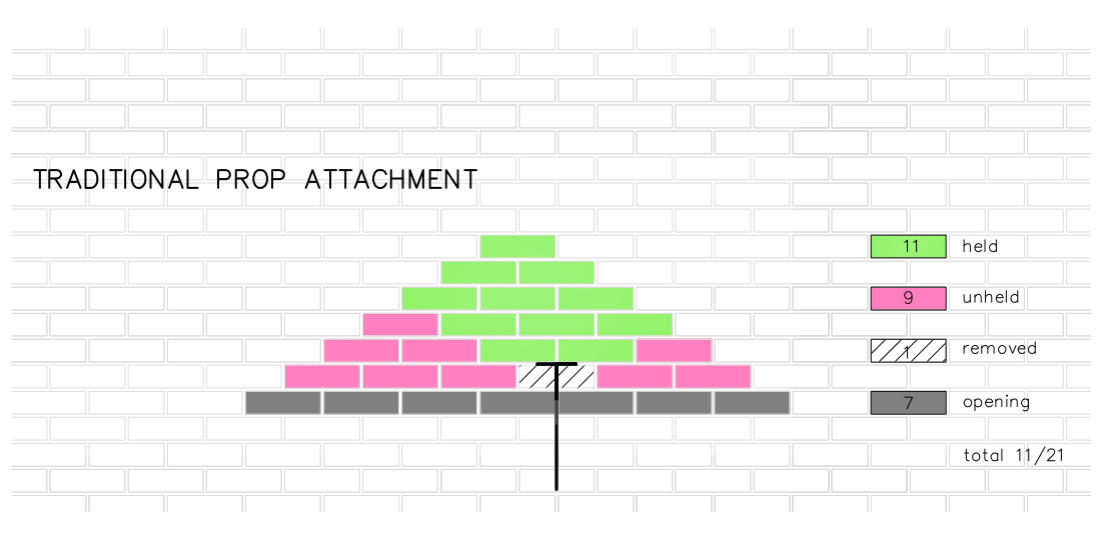

The Brick Brace is the only method that strengthens masonry, to prevent collapse.

–

safety tools are fitted three bricks apart in a cement mortar mix, a maximum of two and a half bricks apart in a weak/ lime mortar mix and within every perpendicular joint upon Block work.

Trial set

Openings of up to 2250mm in a cement mortar mix & 1800mm in a lime mortar mix at any height high or low.

–

BRICK BRACE BENEFITS

Simple to adapt to

Improves Masonry Alterations knowledge

Providing further temporary support options

Keyhole surgery for face brickwork

Full access to the task

Ensures future generations are taught safely & correctly

Use at any height, high or low

Stabilises lime & weak mortar masonry

Increases the variable lateral strength of masonry

No Lost or falling masonry

Fully tested in multiples

Supports all of the masonry, even in lime mortars

Guaranteed superior finish to a task

Versatile & Lightweight

Full access foe scaffolding with no voids or traps

Re-instates a load point to safely reduce the weight of the load

Pays for itself within two applications

Reduced Repair time

Easy To Store/ Fits in a tool bag

Reduced carbon footprint

Designed & Manufactured in Great Britain.

Superior results and time saved

GUARANTEED

–

RESEARCH, Click Here

Tel: 01895 546405

sales@brickbrace.com

Additional information

| Weight | 5.0 kg |

|---|

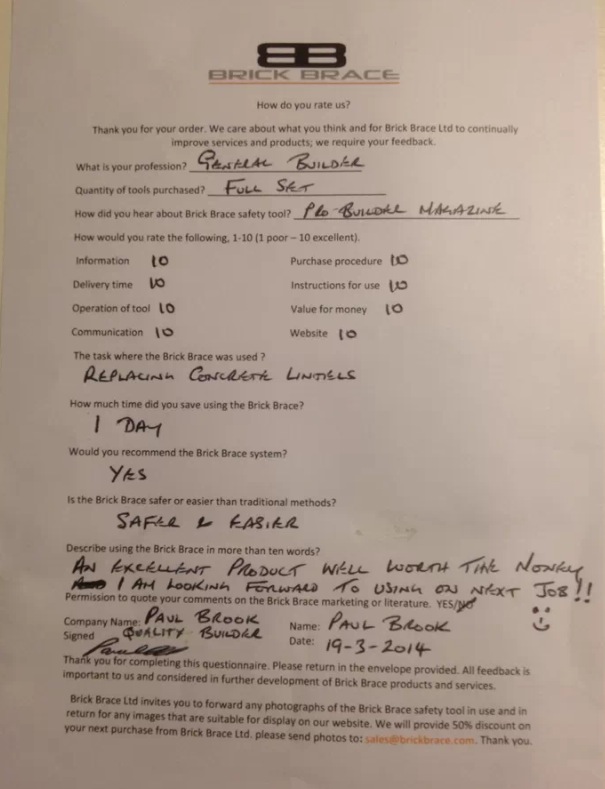

Steve Mansfield (verified owner) –

I first saw Brick Brace being advertised on my Facebook page and it struck me as a simple and effective idea for any structural alterations we might undertake, so I bought a set.

I have just completed my first knock through using them and they worked like a dream, completely stabilising the brickwork course immediately above the proposed position of the RSJ.

On completion and after making good, the building inspector from Lewisham council came out and asked how I carried out the work. After a quick explanation which involved me showing him Brick Brace, the guy was blown away by the simplicity of the concept. It turned out that by trade he was a structural engineer and literally said “why didn’t I think of this”.

As I said good bye to him he said he was going to look into your product and even recommend it to the council.

Looks very much like you may have two converts for the price of one !

I can’t recommend this product enough not only for its simplicity and effectiveness, but also for its ease of use